Our solutions

MicroMétha® offers solutions adapted to everyone.

Depending on the nature and quantity of input to be valued, MicroMétha®

will be able to set up a unit capable to satisfy your projects. Production of heat,

electricity, biomethane and CO2; any type of valuation can be considered and produced by us

thanks to the know-how of our teams and of our partners.

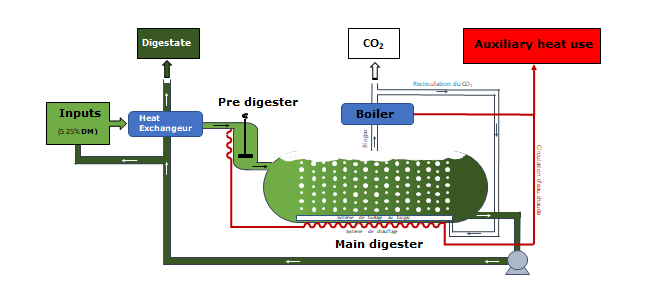

The MicroMétha® unit is of the dry and thermophilic piston type.

For the same volume, the piston digester makes possible to obtain a better rate of conversion

at the outlet, the sludge degrades there gradually from the inlet to the outlet of the reactor.

The digester operates in the dry process, it is fed by a mixture with a dry matter content of

between 5 and 25%. This allows to reduce the water consumption as well as to limit the volume

of digestate produced, a real problem when it is highly diluted. A thermophilic operation

between 50 and 55°C reduces significantly the volume of the digesters by accelerating

the process of microbial degradation. In addition, it allows sterilization of the residual

sludge by eliminating pathogenic microorganisms.

The MicroMétha® process comprises two process phases in the same

digester. The first one, which will be called pre-digestion, ensures the steps of hydrolysis

and acidogenesis: these first two degradation steps are rapid (48 hours) and take place at

acidic pH (approximately 6.5). In the second step, called the main digester, acetogenesis

and methanogenesis take place: these steps are slow (18 days) and take place at a slightly

basic pH (approximately 7.5). Due to their different acidity conditions, the physical

separation of these two steps makes the overall yield much better.

MicroMétha® digesters are cylindrical in shape, with an outside

diameter of 3m, allowing easy transport and installation (on a simple concrete slab).

MicroMétha® digesters are made of fiberglass impregnated with resin

for high resistance to corrosion.

The following table lists the three types

The results presented in this table are provisional orders of magnitude calculated from a typical mixture of inputs. In order to adapt to each situation and each type of input from its customers, MicroMétha® carries out a detailed study to a more precise business plan.

One of MicroMétha® innovations is its biogas recirculation agitation system. It allows efficient mixing of the material being digested while facilitating the release of the biogas being formed. It has three major advantages:

- Avoid the stagnation of biogas microbubbles within the sludge being digested, the presence of which causes local inhibition of methane production

- Avoid the formation of a crust on the surface of the sludge being digested

- Avoid mechanical stirring which poses problems of fouling and maintenance.

On leaving the digester, the biogas is treated in a biogas concentration unit (UCB). The result is a biomethane (@ 90% approximately) which can be used in a standard boiler or in a standard co-generator to produce electricity.

As the MicroMétha® unit working in thermophilic conditions, the digestate produced is sterilized (free of pathogenic microorganisms). Depending on the nature of the inputs, an incorporator can be added in order to grind them finely, homogenize them and mix them with part of the digestate. The benefit is threefold: it saves part of the heat necessary to heat the inputs, adds less volume of water, as well as better initiates their hydrolysis by adding the microbial flora present in the digestate. Downstream of the incorporator is placed a patented heat exchange system which recovers the heat of the digestate to preheat the inputs. Note that for WWTP sludge, an incorporator is often unnecessary. The sludge is exclusively preheated in our patented heat exchanger using the outgoing digestate.

The MicroMétha® unit can be installed both within a wastewater treatment plant and on a farm, we will be able to adapted it to each individual's needs. Typically the principle diagram of the MicroMétha® units for WWTPs and for medium-sized farms are presented below.

MicroMétha® units process scheme for WWTP's

MicroMétha® process diagram for middle sized farms