MicroMétha®for WWTPs

Wastewater treatment is carried out into several stages in WWTP's

(WasteWater Treatment Plant). After having being screened (trapping

of bulky matter) and sieved (finer filtration), the wastewater is

decanted in order to extract the sands (grit removal) and fatty

substances (de-oiling). The water is then sent into an aeration

basin in which the polluting organic matter is degraded by microbial

oxidation. After clarification, an ultimate waste persists, a thickened

sludge (after having being pressed through a screw press) to be

spread on agricultural field. To sanitize it and stabilize its

fermentation, the operator needs often to add lime (operation called

liming).

The grease retained during de-oiling, the organic matter that is

oxidized and the spreading sludge are all carbonaceous materials

that can produce energy. The MicroMétha® process consists in

methanizing this organic material. The biogas produced can then

generate heat and electricity by cogeneration. This biogas can also be

purified into fuel or natural gas.

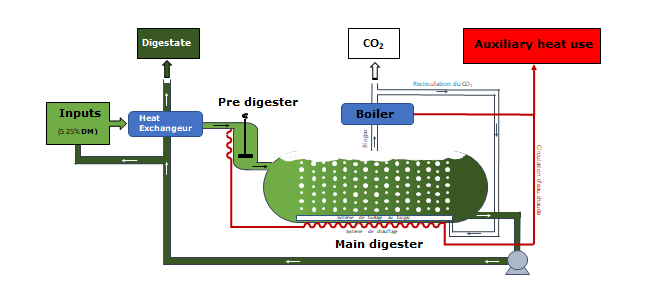

The MicroMétha® methanization unit degrades organic matter into

methane under thermophilic (high temperature) and anaerobic

(without the presence of oxygen or air) conditions. The fermentation

temperature (50-55°C) allows faster degradation than in mesophilic

conditions (35°C) and has the great advantage of sterilizing the

sludge thus avoiding the need for liming. The residence time of the

sludge is shortened by half to release their methanogenic potential

(20 days in thermophilic versus 40 in mesophilic). The result is an

energy production unit twice as compact. A patented heat recovery

exchanger heats the incoming sludge with the outgoing sludge and

considerably reduces the thermal energy input.

MicroMétha® units process scheme for WWTP's

The MicroMétha® unit advantages